Who Are We?

A Global Leader in Modified Atmosphere Packaging Solutions for Fresh Produce

StePacPPC is proud to be part of the PPC Flex family, leading the future of functional flexible packaging together. We make the world a better place via shelf life extension of fruits and vegetables and reducing global food waste.

With over 30 years of experience in combining postharvest, polymer, and packaging expertise, we address major challenges facing the fresh produce industry: supply chain waste reduction, cost reduction, market expansion, and enhanced product quality for consumers.

We provide our customers with added value that includes extended seasonality, shipment to remote destinations via sea freight, reduced waste throughout the supply chain, and enhanced consumer experience through better quality produce.

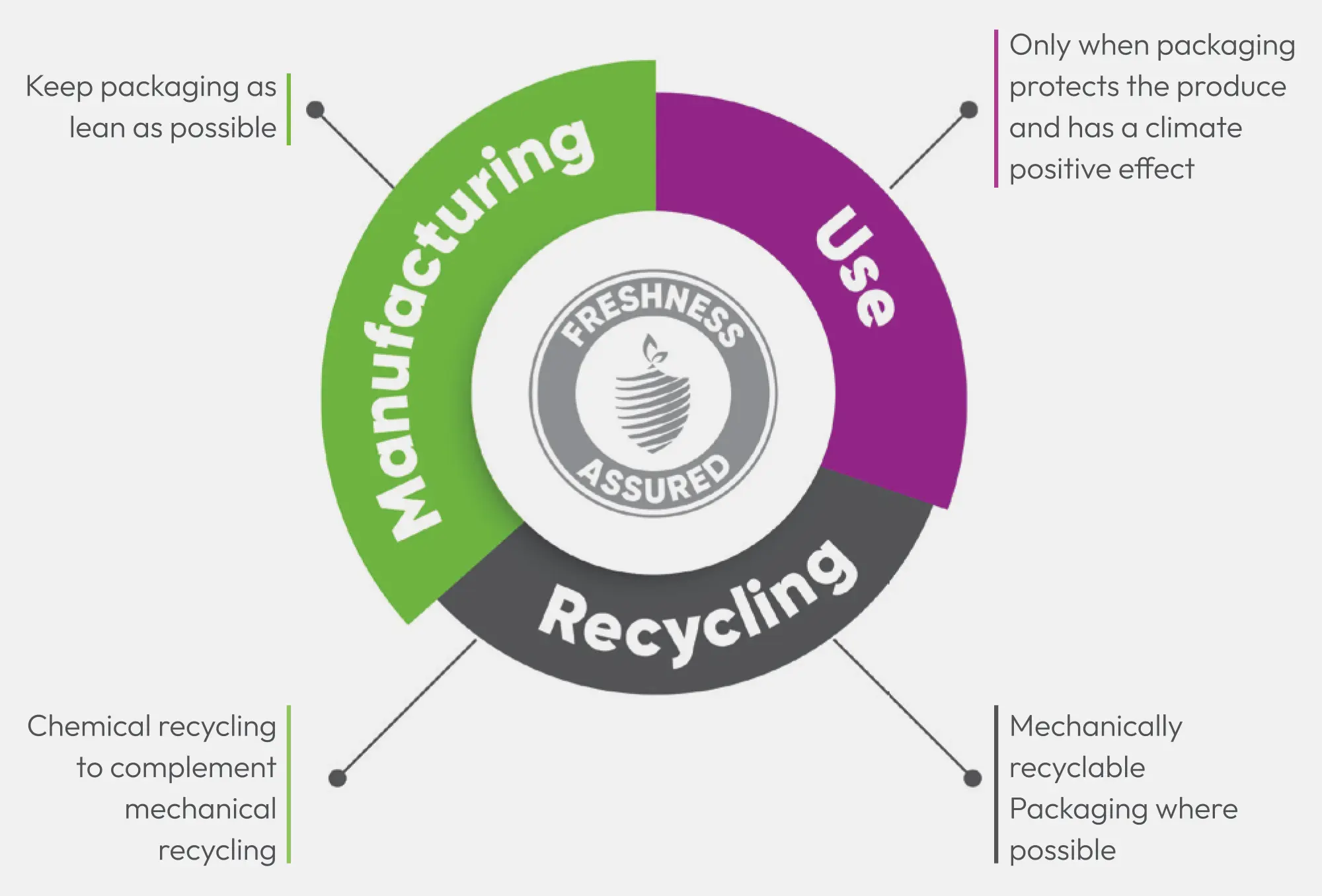

Our broad range of modified atmosphere packaging (MAP) solutions preserve fresh produce quality, reduce supply chain waste and global greenhouse gas emissions.