MAP with a Positive Environmental Impact

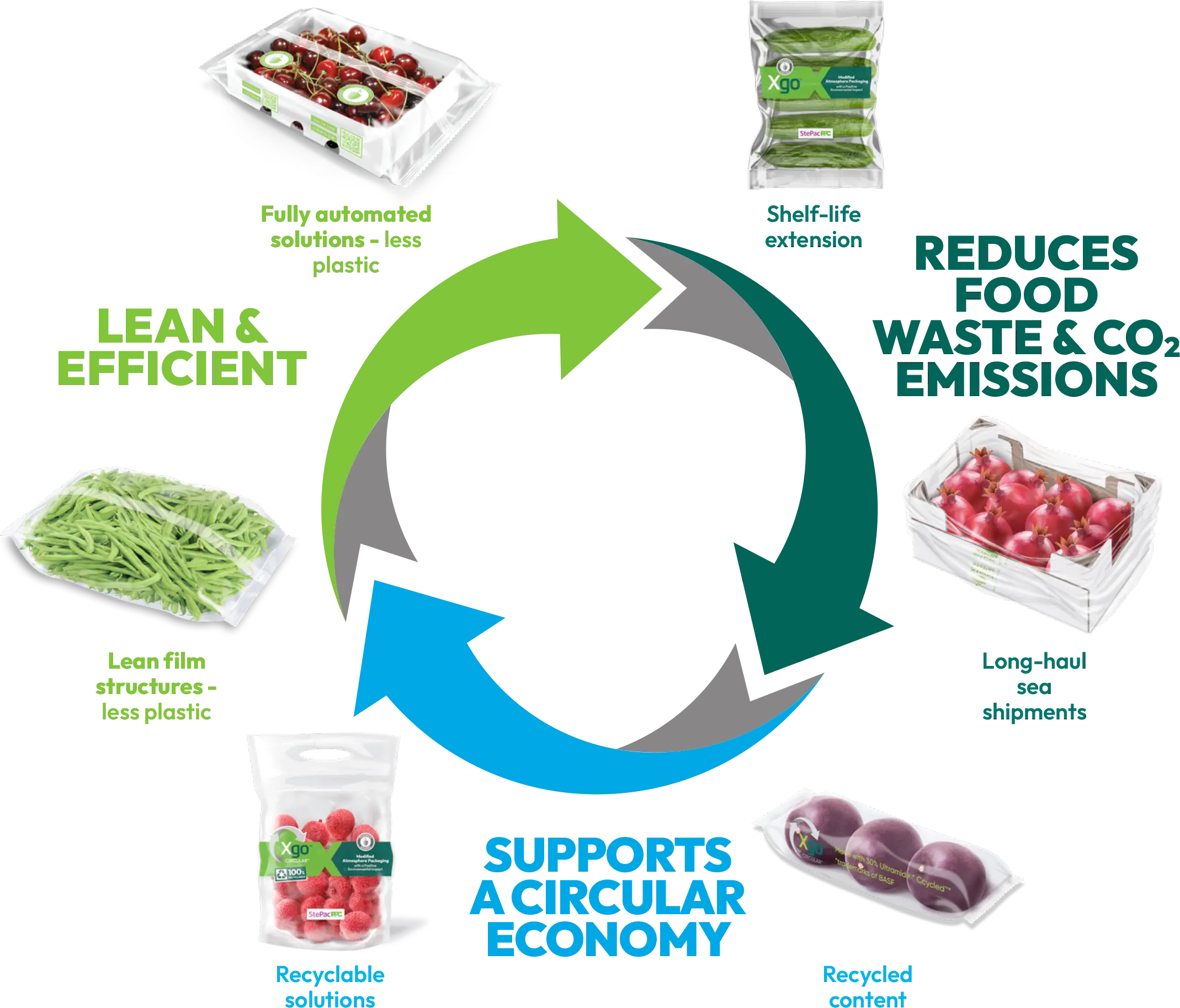

Although society is calling for a reduction in the use of plastic packaging, functional plastic packaging plays an important role in reducing food waste to a minimum. The key is making sure that it is only used when it is really needed to preserve quality and reduce waste, that it is kept as lean as possible and that wherever possible, it can be mechanically or chemically recycled to support a circular economy. At StePacPPC, sustainable packaging is at the heart of everything we do.

At our postharvest and polymer laboratory the StePacPPC R&D team is continuously working to develop the next generation of sustainable packaging solutions for shelf life extension of fresh produce to meet market trends and customer requirements, paying the greatest attention to environmental stewardship.

Packaging for a Sustainable Future

Our innovative packaging solutions extend shelf life and reduce food waste through a four-pillared strategy — climate-positive packaging, lean design, mechanical recyclability, and chemical recycling compatibility. Our approach minimizes plastic use and environmental impact across the fresh produce supply chain.