Proprietary film technology that creates optimal microclimates for produce

Standard packaging falls short in addressing the complex physiological needs of fresh produce for shelf-life extension. Our advanced modified atmosphere packaging of fruits and vegetables goes beyond basic breathable films — combining Modified Atmosphere (MA) and Modified Humidity (MH) control to create the optimal conditions each fruit and vegetable requires.

By reducing oxygen, elevating carbon dioxide, and managing water vapor transmission, we slow respiration rates, suppress ethylene production, and inhibit microbial growth. The result is measurably extended shelf life without compromising taste, texture, or nutritional value.

How Modified Atmosphere Packaging Technology Works

Every fruit and vegetable continues to respire after harvest, consuming oxygen and releasing carbon dioxide, water vapor, and heat. This natural process drives aging, ripening, and eventually decay. Our modified atmosphere packaging of fruits and vegetables creates a controlled environment that dramatically slows these biological processes.

Modified Atmosphere (MA) Control

We regulate film permeability through precision laser perforation to achieve the optimal balance of oxygen and carbon dioxide, extending freshness.

Low oxygen levels and elevated carbon dioxide reduce respiration rates, suppress ethylene production, and inhibit ethylene activity, while elevated carbon dioxide also inhibits the growth of spoilage microorganisms.

Each film structure is customized to create the ideal modified atmosphere for your specific produce.

Modified Humidity (MH) Management

Moisture control sets our technology apart from standard MAP solutions. Our films feature variable Water Vapor Transmission Rates (WVTR) that release excess humidity while preventing dehydration. This specialized capability minimizes condensation that leads to microbial decay — particularly critical for moisture-sensitive produce like berries, leafy greens, and cucumbers. The optimal WVTR for each application is determined by factors including sensitivity to dehydration or excess moisture, the surface area-to-volume ratio of the package, and supply chain conditions.

Good antifog properties are also essential to keep produce visible when condensation forms and to prevent the formation of large water droplets that can promote microbial growth.

Tailor-Made Packaging for Your Specific Produce

StePacPPC’s expertise lies in the development and production of proprietary films with tailored WVTR values, enabling precise control of both moisture and gas permeability to suit the characteristics of different produce types, while accounting for factors such as surface area-to-volume ratio and prevailing supply chain conditions.

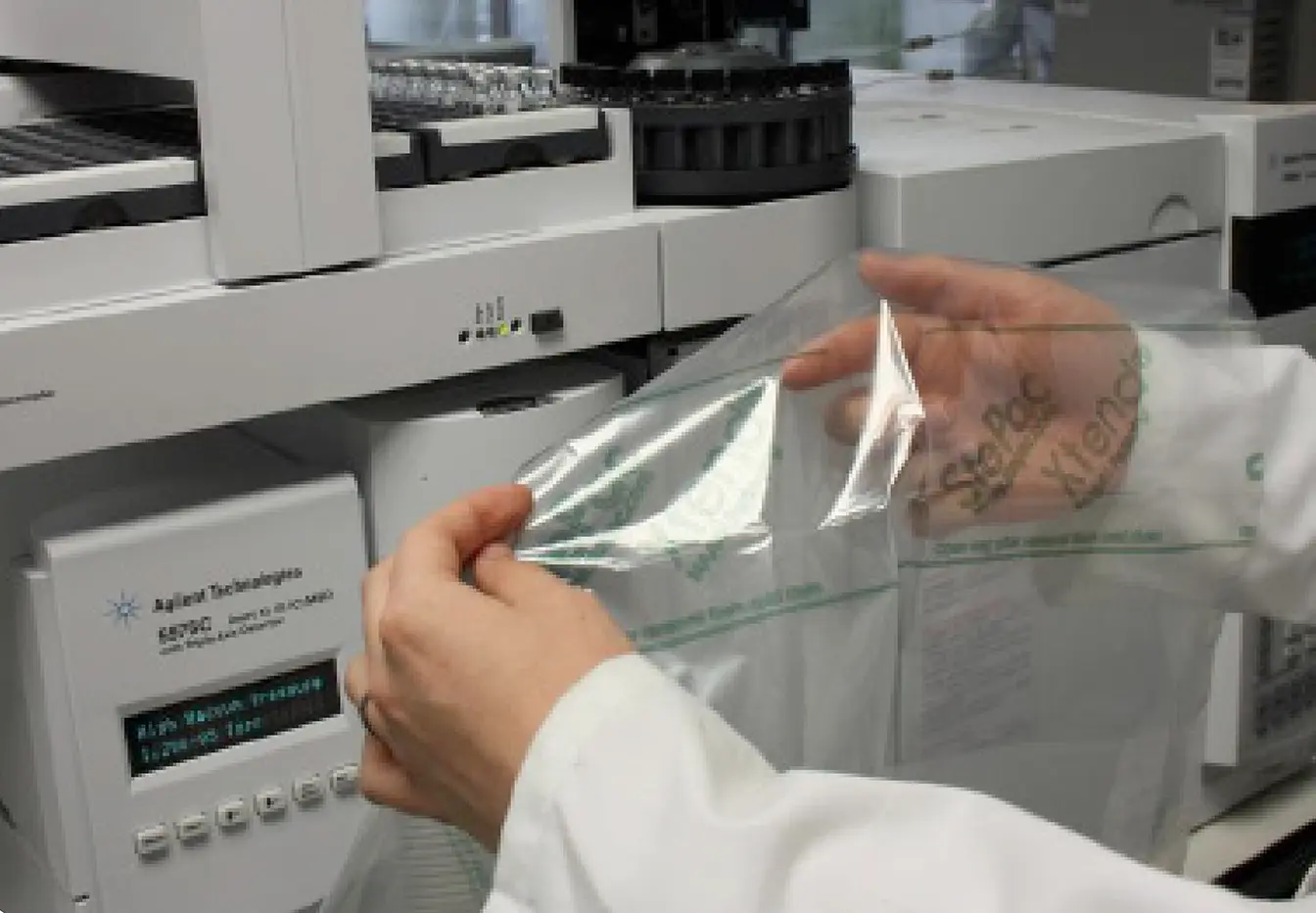

State-of-the-Art Laboratory Testing

Every packaging solution undergoes rigorous testing in our postharvest and packaging laboratory before commercial release. We measure gas composition over time, monitor moisture levels, track quality indicators, and validate shelf life extension under controlled conditions that simulate typical supply chain conditions.

Ideal Microclimate Creation

Our films create carefully balanced packaging environments that maintain optimal conditions for extended shelf life. We account for temperature fluctuations, transit times, and handling conditions to ensure consistent performance from the packing facility to the final destination.

Performance Target Confidence

We provide you with samples and protocols for testing so that you receive full confidence in our products’ ability to meet performance targets before deployment. Our testing protocols are designed to optimize postharvest handling, manage the factors that influence packaging performance and provide the data you need to make informed packaging decisions.

Proven Performance Across 60+ Produce Types

This combined approach has enabled us to develop modified atmosphere packaging of fruits and vegetables for over 60 produce types, resulting in significantly extended shelf life and preserved product quality. It allows stakeholders across the supply chain to:

- Transition from air freight to more sustainable and cost-effective sea freight.

- Extend market reach and seasonality of their produce.

- Reduce postharvest losses and food waste.

- Enhance the consumer experience by delivering produce that looks and tastes better.