Manufacturing capabilities create packaging to the specifications your produce requires

StePacPPC understands that superior packaging performance often starts on the production floor. Our advanced manufacturing capabilities — from multilayer film extrusion to precision laser perforation to specialized converting equipment — allow us to manufacture modified atmosphere bags that deliver consistent, reliable results.

With facilities across the globe through our PPC Flex partnership, we combine cutting-edge technology with rigorous quality control to ensure every product meets exacting specifications. This manufacturing precision translates directly to extended shelf life and reduced waste for your produce.

Difference-Making Manufacturing Capabilities

18+ film structures

with unique MA/MH properties engineered in-house

Array of converting machines

providing unmatched production flexibility

Multiple facilities

across the globe deliver increased reliability and scale

Complete vertical integration

from extrusion through printing to finished packaging

ISO-certified quality management

ensuring consistency across all production

Complete Manufacturing Control: From Film to Finished Packaging

Our vertically integrated manufacturing capabilities enable us to manufacture modified atmosphere packaging with precise specifications at every production stage.

Proprietary Film Extrusion

We operate advanced multilayer blown extrusion lines that produce unique polyamide film structures with customized Water Vapor Transmission Rates (WVTR). By tailoring the core layer composition, we control WVTR to provide optimal moisture management for your specific produce and supply chain requirements. Our portfolio includes more than 18 distinct film structures, ranging from single-layer to custom laminated designs produced not only from polyamide, but also from fully recyclable PE, BOPP and more. Some of our films are also available with 30% advanced recycled content!

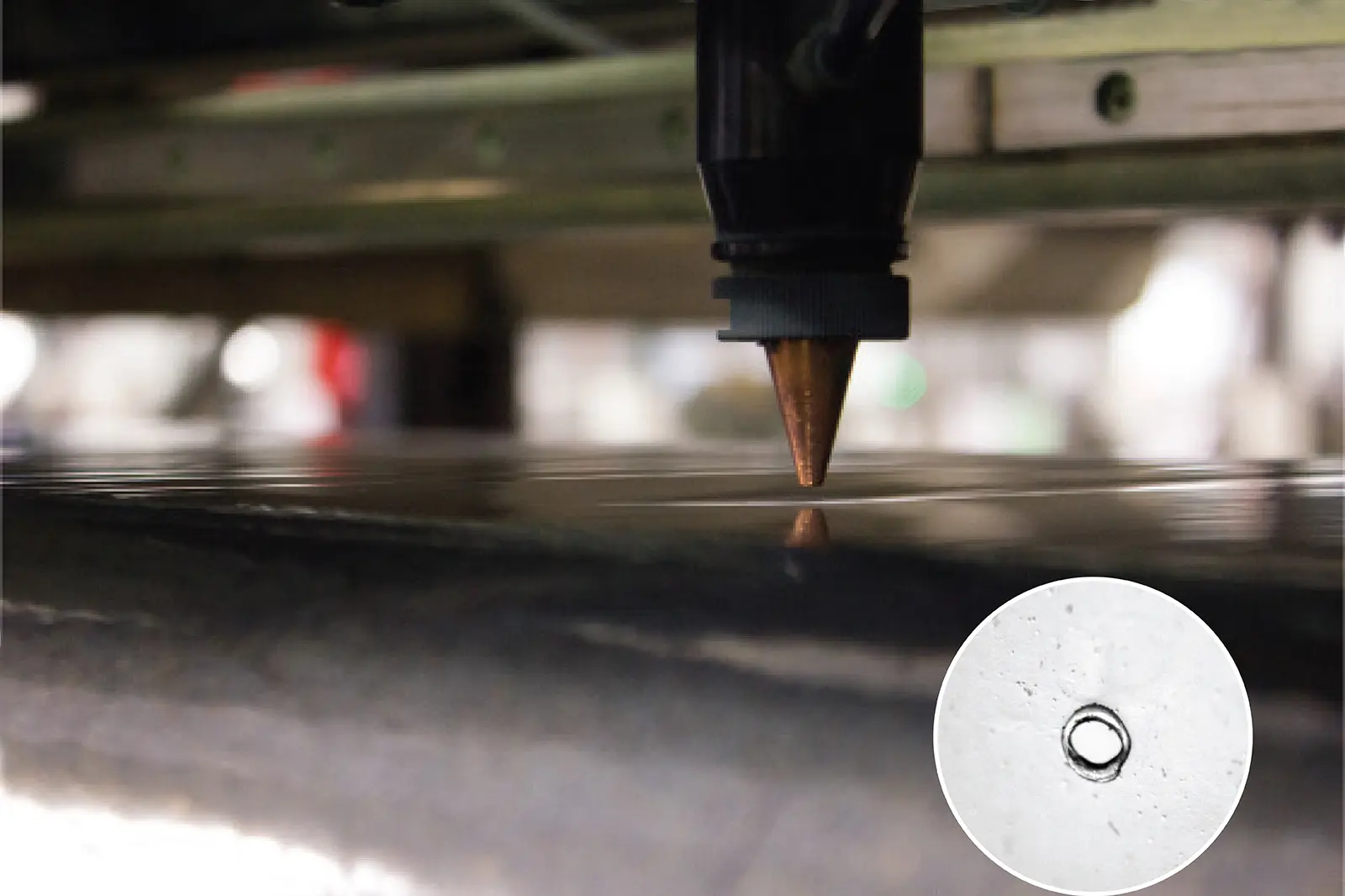

Precision Laser Perforation

We regulate film permeability to oxygen and carbon dioxide through precision laser perforation technology. Depending on requirements, we perforate films on slitters for roll-stock supply or integrate perforation on bag-making equipment for pre-made formats — maintaining exacting perforation patterns for both bulk liners and roll-stock films to retail formats.

Comprehensive Converting

With an extensive array of converting machines, we manufacture modified atmosphere bags in all formats: pallet shrouds, bin liners, bulk liners, roll-stock films, zipper pouches, rear-weld pouches, wicketed bags, and flat bags. This scale serves operations from boutique growers to large-scale commercial packers with consistent quality and customizable sizes.

In-House Printing & Plate Making

Our dedicated printing facilities with in-house plate making ensure reduced lead times and superior print quality. We maintain complete control from design consultation through final production, accommodating complex graphics and brand requirements while preserving technical film performance.

Enhanced Scale Through PPC Flex Partnership

StePacPPC’s integration with the PPC Flex family significantly expands our manufacturing scale and reliability while maintaining the specialized expertise that defines our modified atmosphere bags and packaging.

Manufacturing Excellence

Expanded production capabilities across PPC Flex’s North American facilities complement our Israel operations, ensuring consistent quality and reliable supply for customers worldwide.

Operational Efficiency

Increased production capacity, streamlined processes, and optimized resource allocation across multiple facilities enhance our ability to meet high-volume demands and tight timelines.

Innovation Resources

Greater financial and technical resources accelerate our R&D initiatives, enabling us to bring next-generation packaging solutions to market faster.

Supply Chain Reliability

Robust global distribution network with just-in-time delivery capabilities and local warehousing reduces lead times and ensures consistent availability.

Quality Assurance

All facilities maintain rigorous certifications, including BRC IOP, HACCP, ISO 9001:2015, ISO 14001, and ISO 45001. This ensures that every modified atmosphere bag and packaging solution we manufacture meets the highest standards of food safety, quality management, and environmental responsibility.