45 Days

Achievable Cold Storage/Shipment at 0°C (32°F)

Blueberries face a delicate journey. They are susceptible to weight loss, prone to microbial decay, and quick to lose their prized bloom during long-term storage and lengthy supply chains. Traditional blueberry packaging often falls short, resulting in unrealized potential and diminished profits.

At StePacPPC, we see the potential for a different future. We design packaging that actively preserves the freshness of blueberries for up to 45 days, leading to better quality and reduced waste during extended storage and shipment. Blueberries arrive as vibrant and as fresh as the moment they were picked, even after weeks of transit across oceans and continents.

Our modified atmosphere packaging solutions preserve quality throughout storage and shipment with proven results.

Learn more about our packaging below, or contact our team for a quote.

Achievable Cold Storage/Shipment at 0°C (32°F)

Achievable Shelf Life at 10°C (50°F)

Our advanced packaging technology combines modified atmosphere and humidity control, effectively slowing down the respiration rate, inhibiting the production and action of ethylene, and suppressing microbial decay. Additionally, we offer unique film structures with variable water vapor transmission rates (WVTR) that deliver condensation control for better product visibility and mitigation of microbial decay.

StePacPPC offers a versatile range of blueberry packaging solutions to meet your specific packaging needs. Each solution is designed to maximize freshness, minimize waste and address specific challenges and opportunities in the supply chain.

Conventional bulk liners for manual packing of blueberries. Enable customers to store for longer and supply upon demand or ship to distant markets.

Sustainable solution to protect delicate berries at the full-pallet level. Extend shelf life during long shipments and storage. Made from high water vapor transmission rate films, they tackle the critical challenge of moisture accumulation.

A bulk flow-pack solution, the most innovative alternative to traditional preformed bags for packing and shipping blueberries. Designed for high-speed and efficient packing with up to 40% reduction in packaging material.

Resealable film with 25-30% reduction in plastic use compared to traditional clamshells. Extends shelf-life all the way to the consumer and continues to preserve quality each time the film is resealed.

Easy peel fully recyclable film with 25-30% reduction in plastic use compared to traditional clamshells. Low carbon footprint at 23 micrometer thickness with excellent anti fog properties.

Whether it’s a small local farm or multinational exporter, we help the industry realize the full potential of every blueberry. From Peru to Spain to South Africa, StePacPPC supports farms and exporters wherever they operate.

We proudly provide the following services to customers:

Contact StePacPPC to explore how our advanced blueberry packaging solutions can optimize your operations.

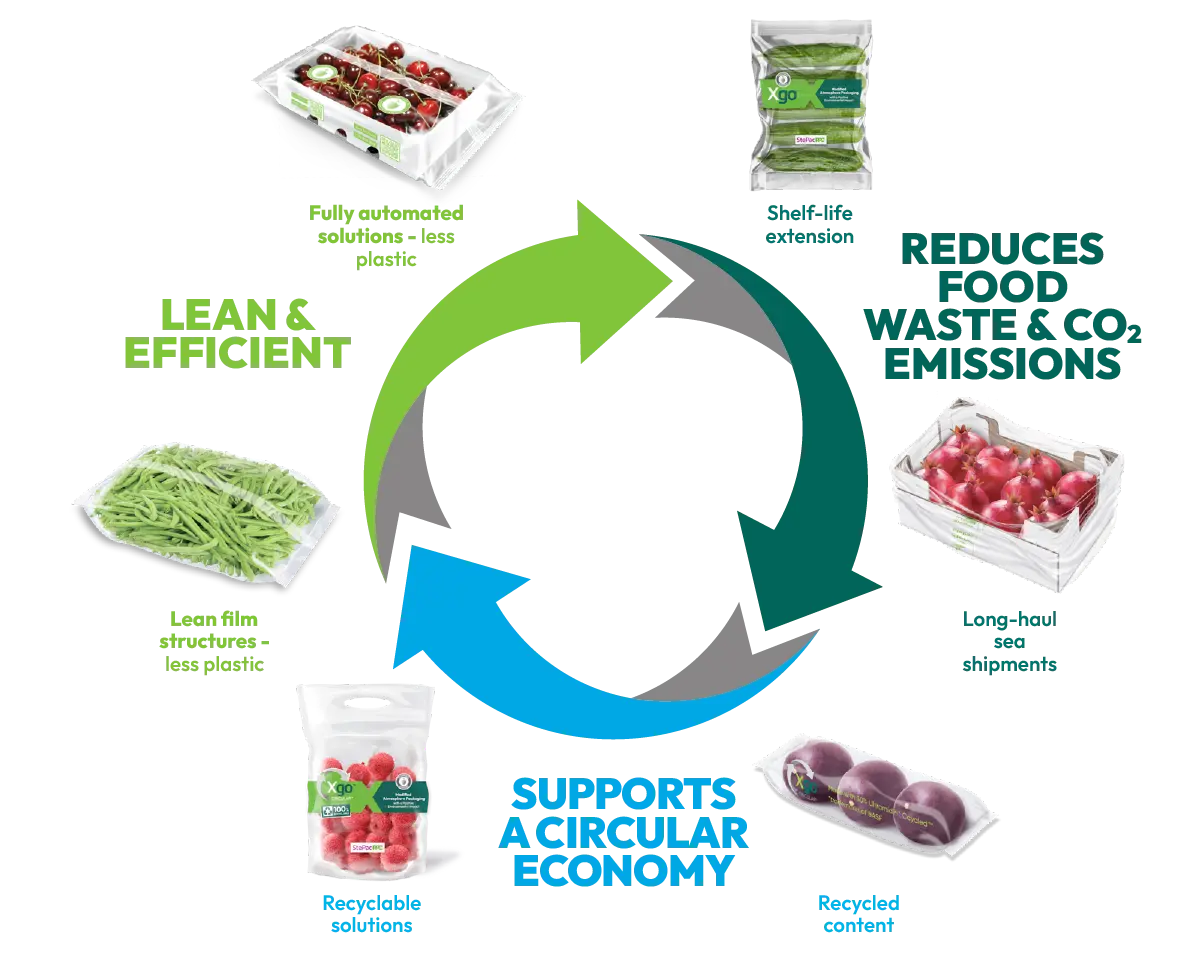

Our commitment to sustainability drives StePacPPC’s innovation. We reduce plastic use, combat food waste, facilitate sea freight over air freight, cut carbon emissions, and offer recyclable options that support a circular economy. We’re also certified by Redcert to incorporate BASF Ultramid® Ccycled®, a chemically recycled polyamide at 30% or more into its polyamide-based films. In many cases, our packaging saves more carbon emissions than are generated during the lifecycle of the packaging. Learn more about our sustainability initiatives here.

Let’s keep your blueberries fresher, longer. Reach out to our team for an initial consultation.