28 Days

Achievable Cold Storage/Shipment at 8°C (46°F)

Major quality issues associated with prolonged storage of bell peppers include dehydration, shriveling, and calyx decay. Proper post-harvest handling combined with precisely engineered modified atmosphere/ modified humidity pepper packaging helps overcome these issues.

In the case of bell peppers, the use of high-water vapor transmission rate films for bulk packaging is key and helps remove excess moisture from the headspace, reducing the risk of microbial decay. Xtend® bulk packaging solutions are designed to slow down post-harvest deterioration and weight loss, while maintaining the natural appearance and texture of the peppers. The film effectively manages free moisture and creates a balanced environment that supports extended shelf life.

Learn more about our pepper packaging below, or contact our team for a quote.

Achievable Cold Storage/Shipment at 8°C (46°F)

Achievable Shelf Life at 20°C (68°F)

Our innovative packaging technology combines modified atmosphere and humidity control, effectively slowing down the respiration rate, reducing weight loss, and suppressing microbial decay of bell peppers. We offer unique film structures with tailored water vapor transmission rates (WVTR) that deliver unparalleled condensation control and moisture management for better product visibility and mitigation of microbial decay.

StePacPPC offers bulk packaging solutions for bell peppers designed to maximize freshness, minimize waste, and address specific challenges and opportunities in the supply chain.

Some of our films are also available with 30% advanced recycled content!

Conventional bulk liners for manual packing of bell peppers. Enable customers to store for longer and supply upon demand or ship to distant markets.

From small local farms to multinational exporters, we’re helping the industry realize the full potential of every bell pepper!

We proudly provide the following services to customers:

Contact StePacPPC to explore how our advanced pepper packaging solutions can optimize your operations.

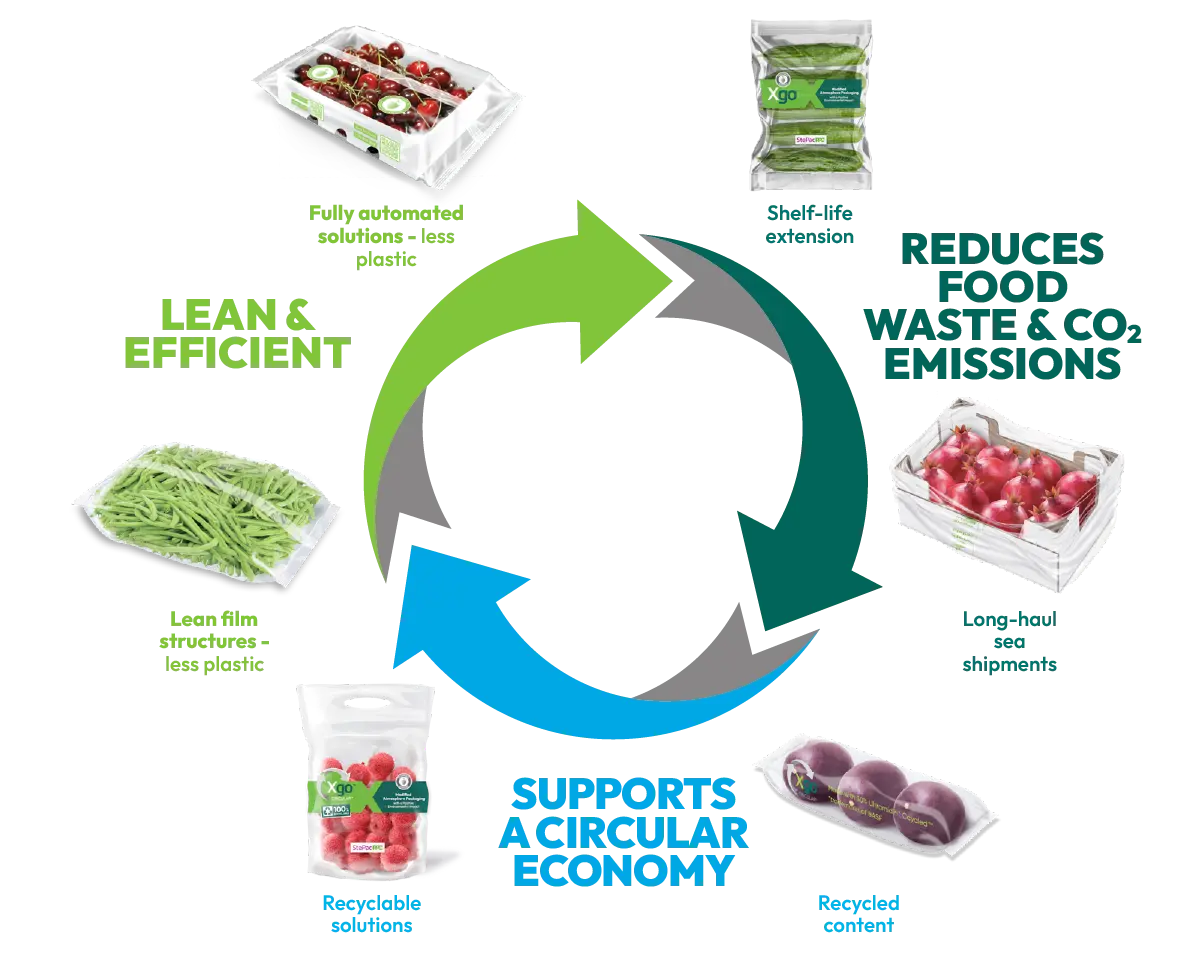

Our commitment to sustainability drives StePacPPC’s innovation. We combat food waste, facilitate sea freight over air freight, cut carbon dioxide emissions, reduce use of plastics and offer recyclable options that support a circular economy. We’re certified by Redcert to incorporate BASF Ultramid® Ccycled®, a chemically recycled polyamide at 30% or more into its polyamide-based films.

Our packaging has a positive environmental impact, saving more carbon dioxide emissions than are generated during the lifecycle of the packaging by reducing waste and facilitating sea freight. Learn more about our sustainability initiatives here.

When you work with us, you’ll keep your produce fresher, for longer. Contact our team for an initial consultation.