Advanced Modified Atmosphere/Modified Humidity Packaging Solutions for Shelf-Life Extension

Fresh cut vegetables are among the most perishable produce items, facing accelerated quality deterioration due to tissue damage from cutting and processing. The exposure of cut surfaces dramatically increases respiration rates, leading to rapid quality loss. Key challenges include excessive moisture loss and wilting, browning of cut edges and exposed tissues, microbial decay accelerated by processing, loss of crispness and texture, off-flavor development, and rapid nutrient degradation. Effective fresh vegetables packaging should address these challenges.

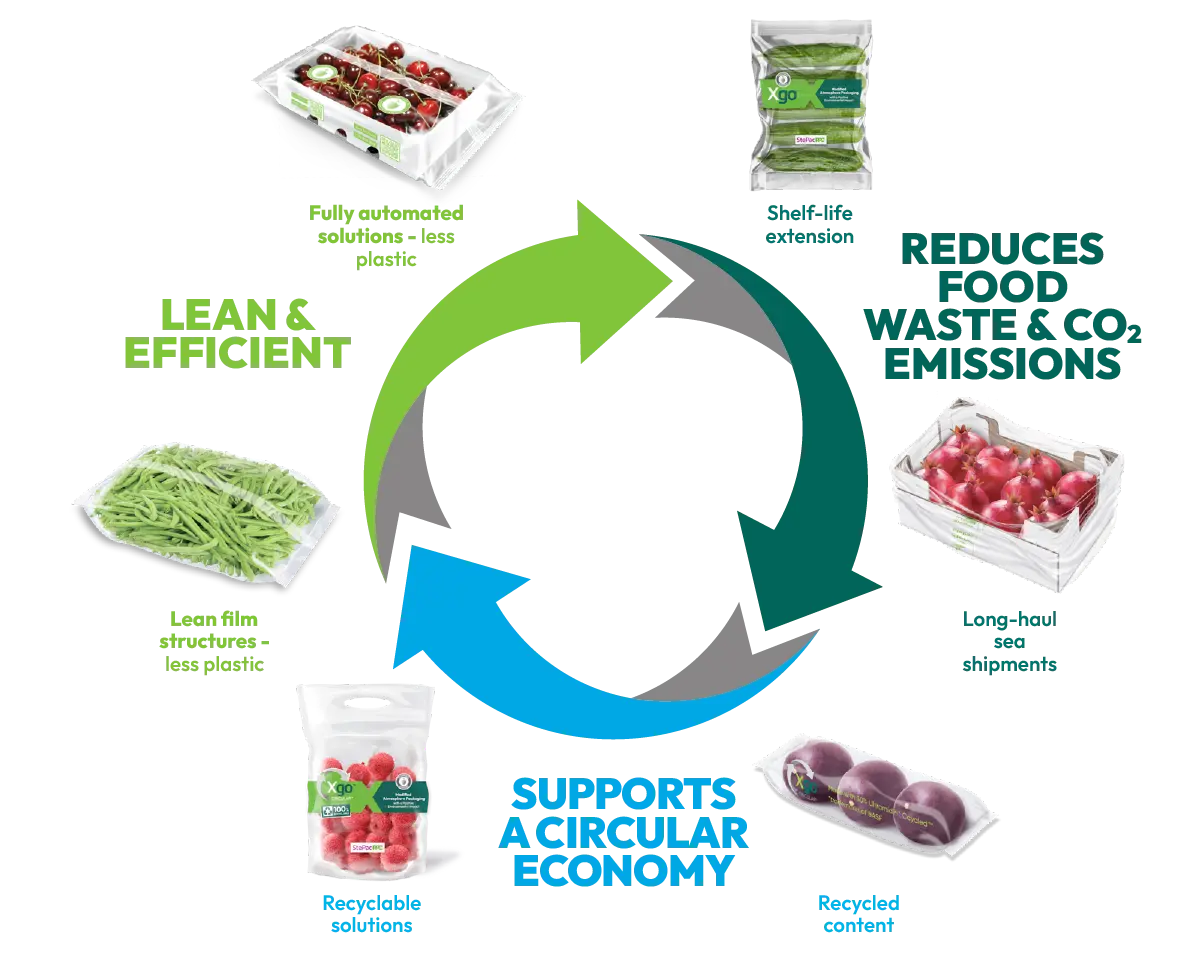

StePacPPC modified atmosphere/modified humidity packaging solutions preserve fresh quality by naturally creating an environment inside the closed packaging that slows respiration, inhibits enzymatic browning, and suppresses microbial decay. Our Xgo™ series of roll-stock films are engineered for high-speed automated retail packaging operations. The films integrate seamlessly with horizontal form, fill and seal (HFFS, flow-pack) and vertical form, fill and seal (VFFS) machinery, delivering consistent performance for fresh cut vegetables.

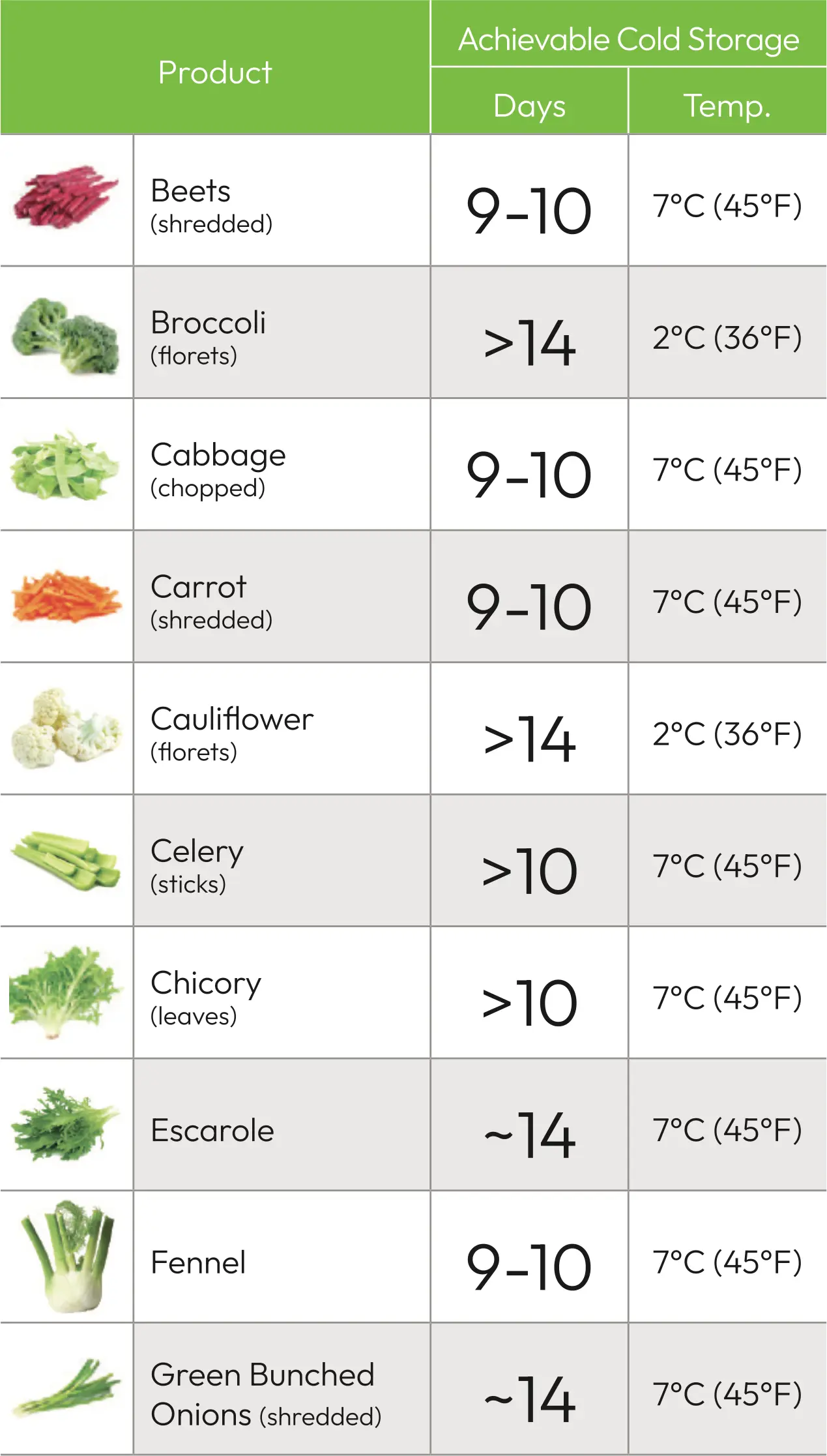

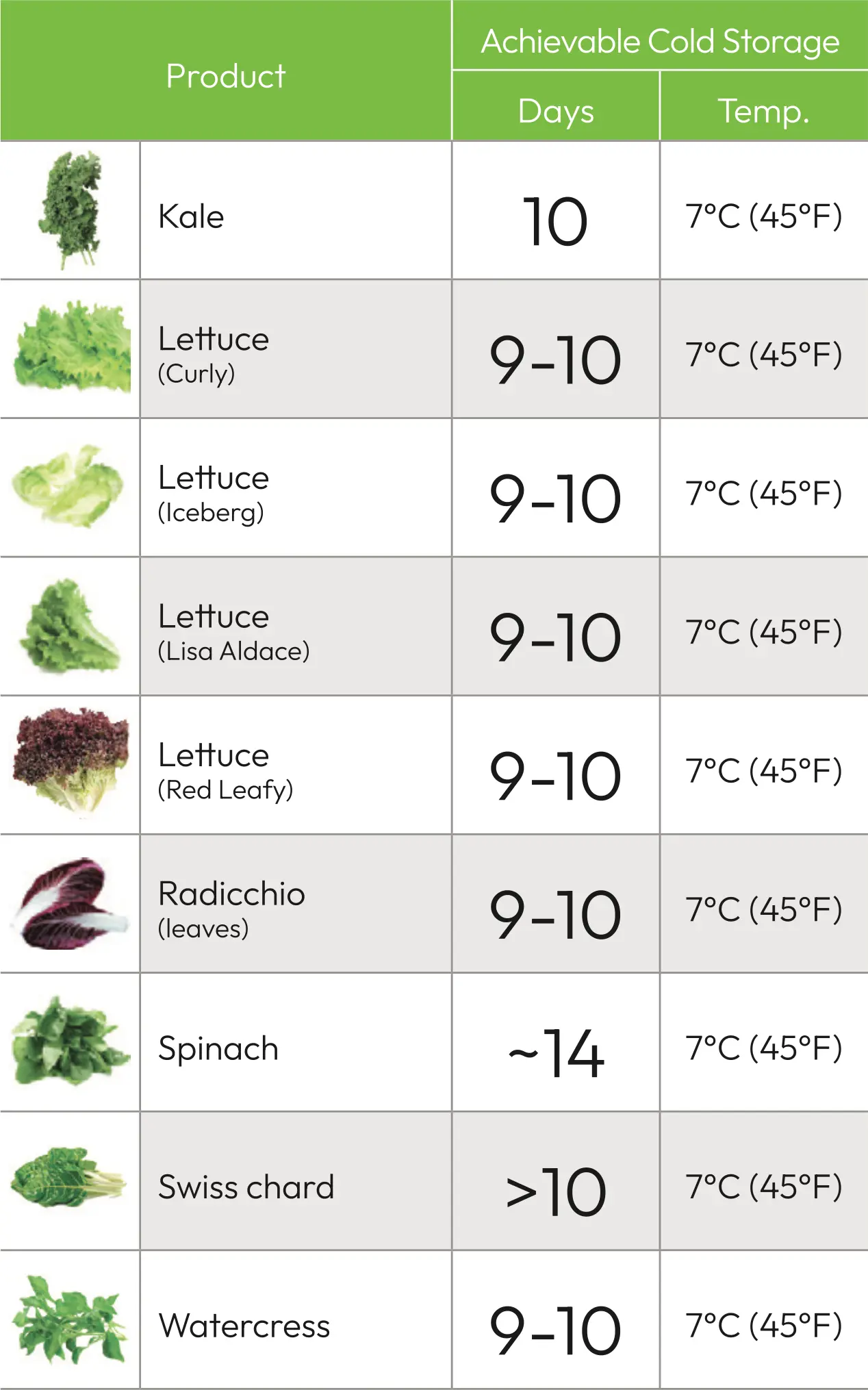

The films contain excellent anti-fog properties that maintain product visibility, which customers respond well to, and are customized to provide optimal modified atmosphere and humidity levels for a wide range of fresh cut items including leafy vegetables, shredded carrots, chopped cabbage, cauliflower florets, cut herbs, and mixed salads.