21 Days

Achievable Cold Storage/Shipment at 0°C (32°F)

Sweet corn is highly perishable due to its high respiration rate, which can lead to the rapid conversion of sugar into starch, reducing quality and sweetness. Challenges associated with extending shelf-life and reducing waste of sweet corn include minimizing dehydration and weight loss, preserving crispness and vibrant kernel appearance, preventing dimpling of kernels, preventing stem and husk decay, and maintaining characteristic sweetness and fresh flavor. Effective sweet corn packaging should address these challenges.

StePacPPC modified atmosphere/modified humidity packaging solutions preserve fresh quality by naturally creating an environment inside the closed packaging that slows respiration, inhibits ethylene, and suppresses microbial decay. High-water vapor transmission rate (WVTR) films are available to help release excess moisture, which also assists in reducing the risk of microbial decay.

In the U.S., sweet corn is packed in ice to preserve its quality during the supply chain. However, StePacPPC’s Xtend® packaging eliminates the need for ice and means much leaner and greener handling and transportation:

We have developed a broad range of packaging formats to meet the needs of different markets and customers Besides Xtend®, our Xgo™ retail packaging solutions enhance consumer experience by preserving quality and broadening the window for consumption.

Achievable Cold Storage/Shipment at 0°C (32°F)

Achievable Shelf Life at 10°C (50°F)

Learn more about our corn packaging below, or contact our team for a quote.

Our innovative packaging technology combines modified atmosphere and humidity control, effectively slowing down the respiration rate, reducing weight loss, and suppressing microbial decay of sweet corn. We offer unique film structures with tailored water vapor transmission rates (WVTR) that deliver unparalleled condensation control and moisture management for better product visibility and mitigation of microbial decay.

StePacPPC offers a versatile range of corn packaging solutions to meet your specific packaging needs. Each solution is designed to maximize freshness, minimize waste and address specific challenges and opportunities in the sweet corn supply chain.

Conventional bulk liners for manual packing. Enable customers to store for longer and supply upon demand or ship to distant markets.

Series of roll-stock films engineered for high-speed automated retail packaging operations. The films integrate seamlessly with horizontal form, fill and seal (HFFS, flow-pack) and vertical form, fill and seal (VFFS) machinery, delivering consistent performance.

Ideal for manually packing and shipping to both local and distant markets.

These bags effectively reduce dehydration, weight loss and quality deterioration throughout the entire supply chain, ensuring the produce reaches the consumer in prime condition.

From small local farms to multinational exporters, we’re helping the industry realize the full potential of every sweet corn!

We proudly provide the following services to customers:

Contact StePacPPC to explore how our advanced corn packaging solutions can optimize your operations.

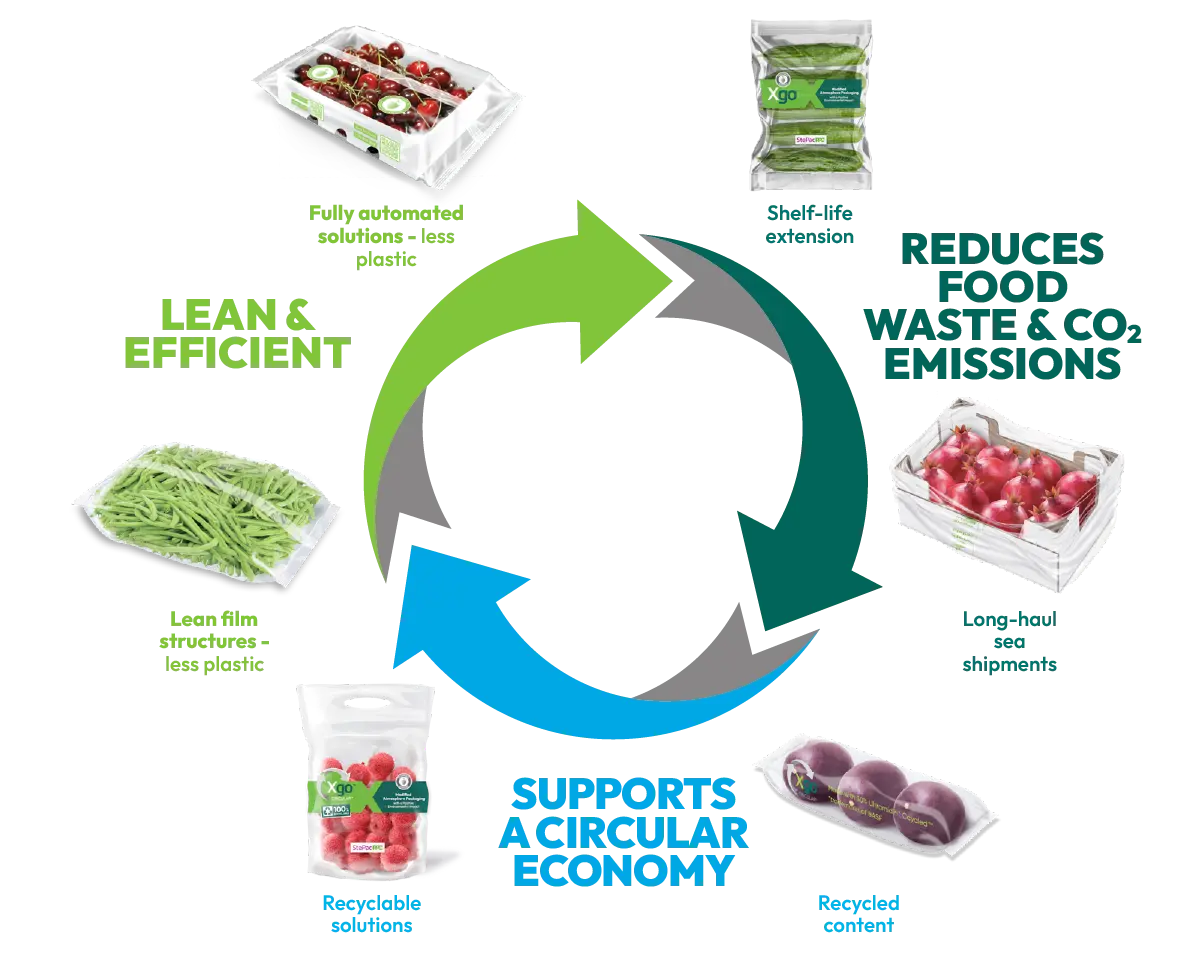

Our commitment to sustainability drives StePacPPC’s innovation. Our packaging solutions reduce food waste, minimize plastic use, support sea freight over air freight, and are available in recyclable formats. We’re also certified by Redcert to incorporate BASF Ultramid® Ccycled®, a chemically recycled polyamide at 30% or more into its polyamide-based films. In many cases, our packaging saves more carbon emissions than are produced during its entire lifecycle. Learn more about our sustainability initiatives here.

We’ll help you keep your corn fresher, longer. Contact our team for an initial consultation.