MAP Packaging Technology That Keeps Produce Fresher, Longer

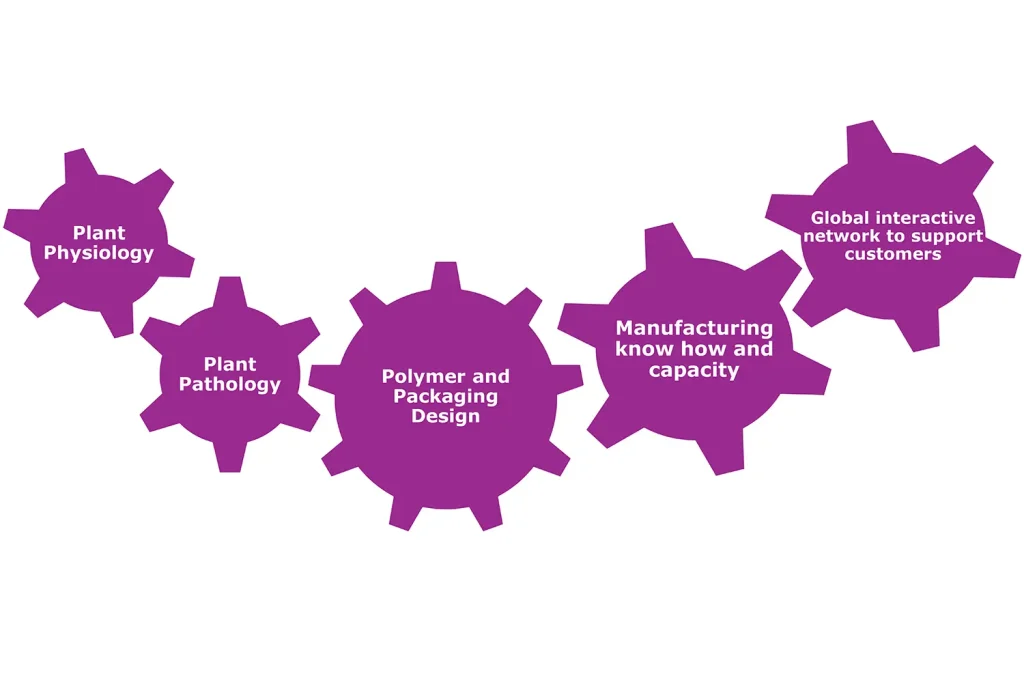

Combining science and advanced materials to create cutting-edge modified atmosphere packaging solutions that maximize fresh produce shelf-life extension.

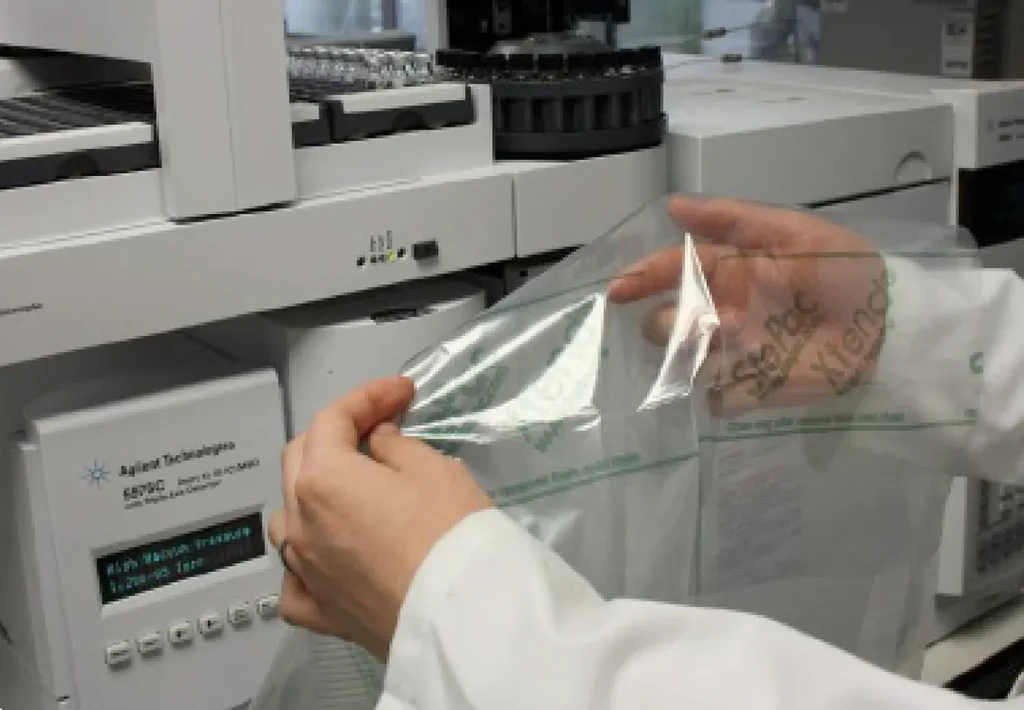

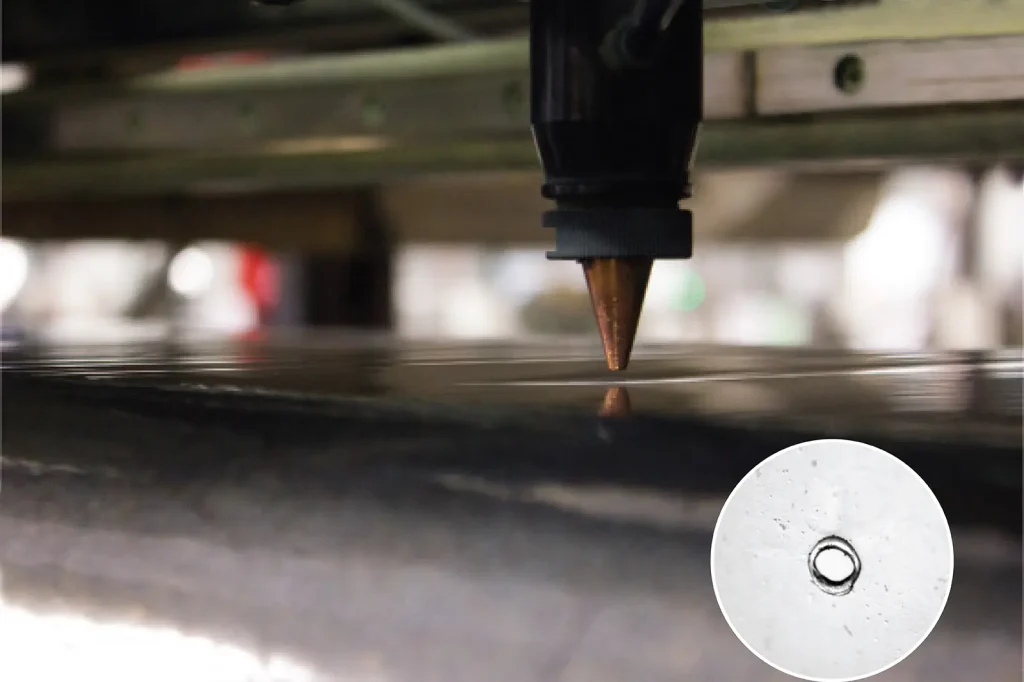

We develop and produce proprietary micro-perforated breathable films that create microclimate environments. Our hermetically sealed packaging regulates the gas composition of fresh produce, preserving freshness, extending shelf life, reducing cross-contamination, and enhancing food safety standards.