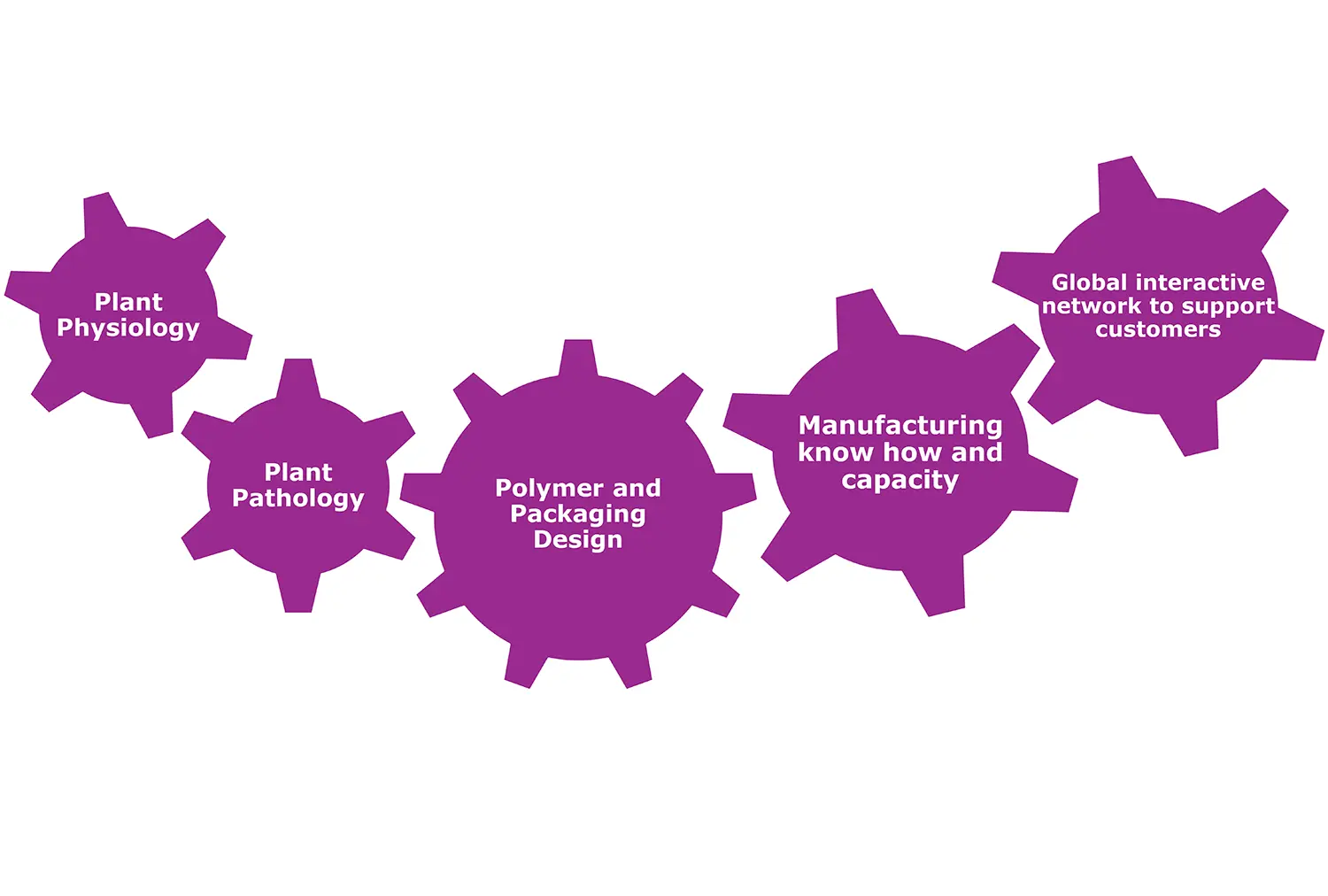

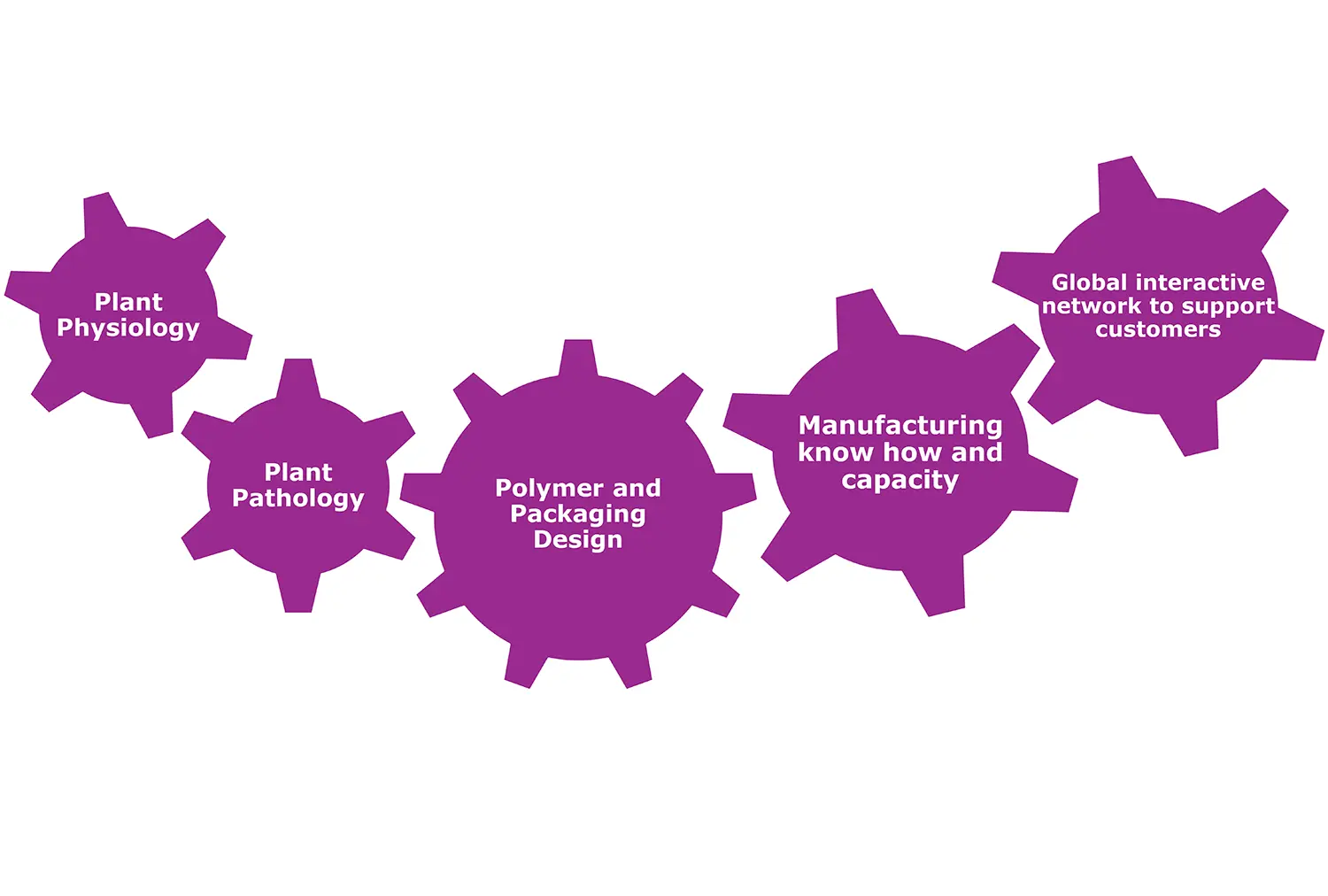

Our deep understanding of produce physiology and pathology, material science, and packaging design delivers optimal performance

Effective produce packaging starts with scientific knowledge, not just material science. Our postharvest handling expertise — spanning decades of combined experience — informs every film structure, every protocol, and every customer recommendation we make. This deep knowledge allows us to engineer packaging and craft protocols that meet your specific supply challenges and preserve freshness and extend the shelf life of fresh produce.

Understanding Produce at the Biological Level

Every fruit, vegetable, and herb has unique postharvest handling requirements driven by its physiology and pathology. Conventional packaging solutions often fall short because they ignore these fundamental biological differences.

Our team possesses expert knowledge of the biological processes that occur in different produce types after harvest — respiration rates, ethylene production and sensitivity, moisture requirements, temperature requirements, susceptibility to chilling injury, vulnerability to specific pathogens, etc. We evaluate how each produce type responds to modified atmosphere conditions, temperature fluctuations, and handling stresses throughout the supply chain.

This scientific foundation allows us to design packaging that creates the precise microclimate your specific produce requires. For instance, the packaging for berries differs significantly from that used for cucumbers, which differs from herbs.

PostHarvest Handling Expertise That Delivers Results

60+ Produce Types

with documented protocols and performance data

25+ Countries

with local field support and technical expertise

30+ Years

applying scientific rigor to real-world packaging challenges

Holistic Approach

The successful development of our packaging solutions requires a holistic understanding of the interactions between the produce and its packaging under the prevailing supply chain conditions.

Hands On Technical Support

We work closely with our customers throughout the supply chain, providing them with detailed postharvest handling protocols and comprehensive technical support to ensure the successful implementation of our solutions. This includes guidance on cooling, sanitation, packing, storage and shipment practices — all critical to controlling the factors that influence performance. Our collaborative approach helps ensure consistency, uniformity, and optimal effectiveness, maximizing the value of our packaging solutions for our customers.

Custom Solutions Engineered for Your Produce

Our packaging recommendations account for your produce-specific characteristics: respiration rate, sensitivity to moisture accumulation, sensitivity to dehydration, ethylene production levels, and your supply chain’s temperature-time profile. We also consider harvest maturity, pre-cooling methods, packing house conditions, and distribution logistics to ensure our solutions perform effectively in your real-world environment.

The Importance of Close Customer Relationships

A key factor in our ongoing innovation is our strong and close customer relationships, which enable us to deeply understand their specific needs and stay attuned to emerging market trends. This collaboration fuels our ability to develop the next best thing in packaging solutions that continually meet and exceed market demands.

Global Reach, Local Touch

From small local farms to multinational exporters, we help the industry realize the full potential of every produce.

We proudly provide the following services to customers:

- Local expertise combined with global knowledge

- On-site postharvest audits

- On-arrival inspections

- Multilingual technical support

- Customized training programs

- Product simulation, testing and benchmarking